June 29, 2011

Revolutionary radiation-sensitive plastic (trademark "Scintirex") with a performance superior to plastic scintillators used for measuring radiation and enabling a major reduction in production costs

~ A step toward an inexpensive radiation detector available to everyone ~

Dr. Hidehito Nakamura and Dr. Sentaro Takahashi at Kyoto University Nuclear Reactor Research Institute (Headed by: Hirotake Moriyama), Dr. Yoshiyuki Shirakawa at the National Institute of Radiological Sciences (Managing Director: Yoshiharu Yonekura), and Mr. Hisayoshi Shimizu at Teijin Chemicals(CEO: Kazuyuki Sakai) have been successful in developing a revolutionary radiation-sensitive plastic (trademark "Scintirex") at a dramatically reduced cost (one-tenth or less), that outperforms plastic scintillators, important components in radiation detectors that have become widely used by stakeholders in nuclear power plants and local council workers.

Radiation detectors that utilize the results of this research will make major contributions to radiation management essential to the nuclear power industry in general, contamination management in far-reaching locations, and to radiation management at nuclear power plants around the world. We expect these detectors to be adopted not only by nuclear power plants, but by 6,000 radiation stations (including hospitals) in Japan. We also expect them to answer a demand for inexpensive, high-performance radiation detectors among the general population. Looking to the future, we will conduct more product development in order to achieve a large market share in the international market, currently monopolized by foreign companies, through Japan's strengthened cooperation among government, industry, and academia.

These results were published in the online version of Euro Physics Letters (EPL) on June 29, 2011.

Summary of Research Results

- We have succeeded in developing a revolutionary radiation-sensitive plastic (trademark "Scintirex") with a performance superior to plastic scintillators currently used for measuring radiation.

- Production is now possible at a greatly reduced cost of less than one-tenth the cost of existing radiation detector products in overseas monopolized markets.

- We aim to strengthen cooperation among government, industry, and academia and provide people who live near nuclear power plants in Japan and overseas with inexpensive, sturdy personal dosimeters and survey meters for contamination monitoring. At the same time, we will contribute to widespread nuclear power safety activities.

I. Context and Goals of Research

Radiation detectors are now being used not only by researchers, but by many other people, including the general public, as radiation management devices providing safety and peace of mind to those living near the world's nuclear power plants. They were essential devices in responding to the Fukushima Dai-ichi Nuclear Power Plant disaster that followed the March 2011 earthquake that occurred in the Pacific Ocean offshore from the Tohoku region. In particular, every year some billions of yen worth of plastic scintillators formed only with hydrogen and carbon are used. The market is monopolized by foreign companies, however, and increasing demand has recently lead to major price increases. Further, the special grinding process performed on the surface of plastic scintillators to efficiently detect the light they generate thwarts cost reductions through mass-production.

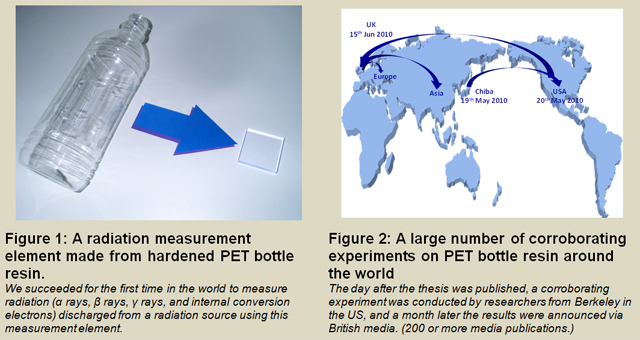

To overcome these circumstances, Dr. H.Nakamura and his associates have been conducting research into substitute products for plastic scintillators. The result was the 'Columbus' Egg'-style discovery that allows even a PET bottle, a plastic product with which we are all familiar, to be used to measure radiation, and radiation measurement based on PET bottle resin was demonstrated (May 2010). Further, in contrast to the plastic scintillators used today that only contain carbon and hydrogen, chemical analysis indicates that the oxygen contained in PET bottle resin results in higher density, refractive index, radiation reaction cross-section, etc., compared to the plastic scintillators. PET bottles are thus actually well-suited to radiation measurement and light propagation.

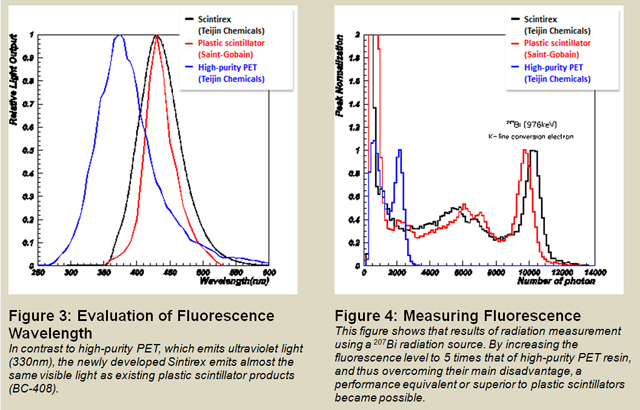

These research results were a major news event not only in Japan but globally. Corroborating experiments on radiation measurement using the resin from PET bottles, polyethylene terephthalate, were conducted around the world in research institutions and major foreign corporations, and the performance of this material was verified. PET bottle resin performance, however, was inferior to plastic scintillators from the two perspectives of the volume of fluorescence generated when radiation strikes, and the wavelength of the fluorescence.

In this research, we took on the challenge of developing a revolutionary radiation-sensitive plastic that exhibits better performance than currently used plastic scintillators, in order to gain a share of the international market for plastic scintillators, and to respond to the increasing demand in society for an inexpensive radiation detector.

II. Research Method and Results

In this study, we selected monomers to determine the molecular structure of the radiation-sensitive plastic and modified the various types of polymerization catalysts to surpass the performance of plastic scintillators with a molecular structure similar to that of the plastic resin of PET bottles. As a result, we successfully developed Sintirex (patented). In addition, we compared its qualities with plastic scintillators from Saint-Gobain, which are currently the most widely used type globally.

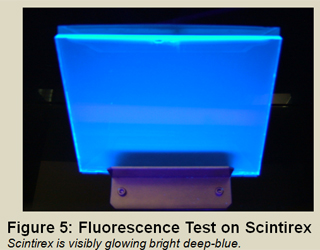

The results indicated that the Scintirex developed was an extremely strong plastic exhibiting a performance equivalent or superior to plastic scintillators. It was primarily composed not only of carbon and hydrogen but also oxygen, and had a density of more than 1.33g/cm3, a refractive index of 1.65 or greater, a maximum wavelength in the visible light range, and a fluorescence level of 10,000 photons or more per 1MeV (Figures 3, 4 and 5). Because Scintirex is ubiquitous in our personal lives, a substantial cost-reduction can be achieved compared to plastic scintillators currently used. Further, taking advantage of the fact that Scintirex is extremely easy to fabricate, it became possible to develop radiation detectors in many different shapes.

III. Results of This Research and Future Outlook

In this research, we overcame the fluorescence level weakness of PET bottle resin (by a factor of 5), and succeeded in developing a revolutionary radiation-sensitive plastic that exhibits equivalent or superior performance to current plastic scintillators while simultaneously lowering the cost substantially (to one-tenth or less)(Table 1). Teijin Chemicals is currently applying for a trademark on "Scintirex" for the radiation-sensitive plastic containing high-purity PET.

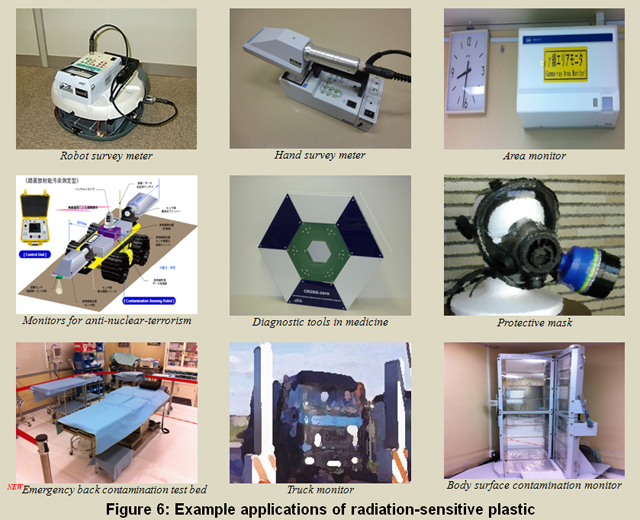

Just by replacing the currently used high-cost plastic scintillators with the newly developed radiation-sensitive plastic, this material could immediately be used in a broad range of areas. In the nuclear power sector, for example, we estimate there is demand for radiation management devices that use plastic scintillators from power plants, nuclear fuel processing plants, and radiation facilities (total of 6,000 facilities).

Specifically, this material is used mainly in portable survey meters, hand/foot clothing monitors, water monitors and gas monitors etc (a total of over 20,000 devices). Further, as a result of future research and development, it may become possible to use this material in equipment for testing for illegal radioactive substances in airports, port facilities, railway stations, etc., around the world. If radiation-sensitive plastic could be used in larger quantities, it is likely that the production of devices never before available could become feasible through use of a high-speed, high-sensitivity method. These might include walk-through contamination monitors (which can measure the contamination of many local residents, or nuclear power plant workers in real time), drive-through truck monitors (which measure trucks and work vehicles in real time), whole-body counters (until now a separate detector has been used; a person enters a small plastic room and the contamination present is measured promptly). Further, through applications in medicine and other fields, practical implementation in low-cost medical diagnostic tools (radiation cameras, etc.) and diagnostic tools for large animals (horses, cows, etc.) might be possible. We would expect the technology to be used in monitoring for the storage and management of radioactive material kept in hospitals and all kinds of research institutions (Figure 6).

Also, outside the field of radiation, utilizing the material's characteristics of refractive index and fluorescence wavelength, application in low-cost optical fibre in the telecommunications sector is being investigated. Consideration is also being given to use as an educational resource for learning about radiation in primary and high schools.

IV. Glossary

Scintillator

A substance that emits fluorescence when struck with radiation. When radiation passes through the substance, the electrons in it are shifted to a slightly higher energy state (excited state), and the excited electrons return to their original state within a very short time span of between 100 microseconds to 1 nanosecond, and during this time a light called scintillation light is emitted. Scintillation light is extremely faint, and cannot be used as is to measure radiation or elementary particles. In the 1940s, a scintillator was developed with a wavelength conversion agent added to it, enabling detection of radiation using scintillation light.

polyethylene terephthalate

A type of polyester abbreviated as PET and used in PET bottles, known for its use in beverage containers, and as the base material for film and magnetic tape, as well as fibres, etc., for clothing. Among thermoplastic synthetic fibres, it is relatively heat-resistant due to its crystalline nature, and it is produced in the largest quantities. As a result, it is also one of the resins most commonly recycled as fibre from PET bottles.