Starch biomass (eg, cassava pulp and food waste) is a cheap and abundant renewable carbon source in bioethanol production. Therefore, it may be important to develop low cost ethanol production processes with a suitable energy balance in order to foster the development of a low-carbon society.

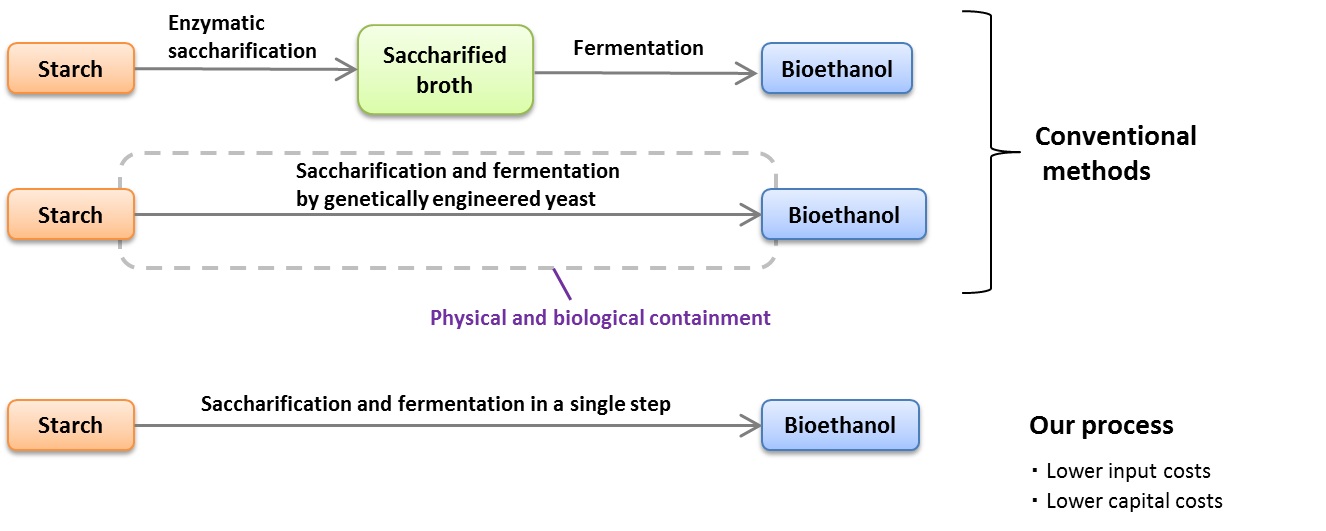

At present, the cost associated with supplying the enzymes required to produce bioethanol makes it a less competitive fuel. Eliminating the need for amylases in bioethanol production is a key step toward reducing its operating costs. Consolidated bioprocessing (CBP), which integrates enzyme production, saccharification, and fermentation in a single reactor and a single yeast strain, is a promising strategy for low cost ethanol production from starchy biomass.

In this study, to gain insights into bioethanol production from starch through CBP, a comprehensive screening was performed for natural isolates of yeast that could produce ethanol without the need for addition of amylases.

We examined the ethanol-producing ability of yeast strains isolated from soil samples in the Kyoto area. Of the 530 yeast strains tested, 3 strains ( Scheffersomyces shehatae JCM 18690, ATY945, and ATY1112) were found to produce more than 6 g/L ethanol. The fermentation profiles of the 3 strains were examined. After 10 days of cultivation, ethanol production by S.shehatae JCM 18690 reached 9.2 g/L. To gain insight into the ethanol-production ability of S.shehatae JCM 18690, changes in the concentrations of starch and glucose generated by amylases from starch and the amylase activities were monitored in starch liquid medium. Therefore, the glucoamylase activity of S.shehatae JCM 18690 was significantly higher than that of the other strains. This result indicate that the increase in the ethanol concentration of S.shehatae JCM 18690 was mainly due to the increase in its glucoamylase activity.

Fig. Various bioprocess methods available for the conversion of starchy biomass to bioethanol.