Research continuum

Backstage at the lab

The high-tech astronomy of Seimei

Building East Asia’s newest and largest telescope

Human knowledge, like the universe, is constantly expanding. And now our ability to observe the heavens is about to expand even further.

In 2006 Kyoto University, Nagoya University, the National Astronomical Observatory of Japan (NAOJ), and Nano-Optonics Energy Inc began an over decade-long project to construct the largest telescope in East Asia. The “Okayama 3.8M Telescope”, recently nicknamed Seimei after the historical onmyoji and astrologer, will finally aim for the stars in late 2018. But it’s not just its sheer size that’s impressive: equipped with innovative new technologies, Seimei will be unrivaled in its speed and accuracy as it combs the cosmos.

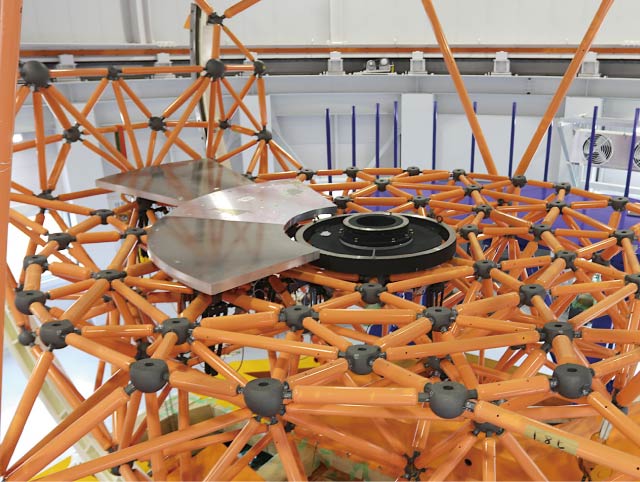

March 2018: Project team member Masaru Kino explaining Seimei’s groundbreaking design

Bridging the skies

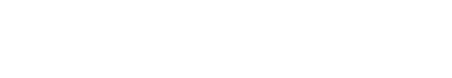

March 2018: The telescope awaiting its mirrors

March 2018: The telescope awaiting its mirrors

East Asia has until now lacked a multipurpose, optical infra-red telescope with a diameter larger than 2.5 meters. This gap in terrestrial astronomy’s ability to gather high-quality data around the globe meant that if a cosmic phenomenon — such as a massive stellar explosion — were to suddenly appear over this hemisphere, crucial first records would be lost.

Initial observations of giant stellar events are critical for researchers, but their rarity and unpredictability require constant, careful monitoring of the night sky. So this blindspot over Asia has been a planet-scale weakness.

For the telescope itself, it’s not just about being bigger and better; this new scope heralds a coming generation of high tech eyes on the sky. And what better place to put it than the Okayama Astrophysical Observatory in west Japan, home to an historical 188 cm telescope that — when completed in 1960 — was also the largest in Asia.

The Okayama Observatory, managed by NAOJ, working together with leading telescope technology developers at Kyoto University and Nagoya University, formed a team with the common goals of increasing the efficiency of construction as well as the movement and capture speed of the telescope itself.

The final hurdle was project funding, which is often difficult to surmount in Japan due to a lack of philanthropic traditions. Fortunately one KyotoU graduate thought differently, leading to Nano-Optonics Energy Inc contributing over a third of the project’s total cost. And so with all the pieces in place, in 2006 the 3.8M telescope project was formally launched.

Next-gen tech

“Three key technologies define this telescope,” explains Masaru Kino of KyotoU’s Graduate School of Science. “Its quick-slewing mount, segmented mirror design, and the mirror grinding itself. We have focused on improving speed and accuracy, since we plan to specialize in observing short-lived astronomical phenomena.”

Superflares are one such event type. Similar to our sun’s flares, these occur on distant stars with many times the energy level. Gamma-ray bursts are another target, consisting of violent eruptions of radiation from massive stars. And then there are black hole binaries, where a black hole and an ordinary star orbit each other. Each of these is extremely difficult to observe, as they only last for a brief period of time.

To make such observations with any accuracy, the telescope needs to be moved quickly. This is where the quick-slewing mount comes in: made of light-weight materials, the telescope’s striking lattice structure — considerably shorter than its 188 cm predecessor — can be readily rotated by just one or two people.

The additional leading edge technologies are to be found in the telescope’s heart. Mirrors for observatory telescopes aren’t made from ordinary glass. In order to capture the night sky with the utmost precision, the highest possible quality glass must be used, which becomes a limiting factor on total size.

The 3.8M teams’s radical solution was to break up the mirror into 18 petal-like segments. Previous segmented designs have used hexagons.

“These ‘petal’ segments are a world’s first, and as a result we expect to obtain higher optical performance than with existing designs,” Kino says.

July 2018: The mirrors in place at last!

July 2018: The mirrors in place at last!The 18 mirror petals are laid out in two concentric rings — six on the inside and twelve outside — with each segment weighing about 70 kg. These are then mounted onto individual actuators that control the mirrors’ orientation with nano-scale accuracy. So when the telescope has been reoriented — or even when the dome is opened and wind pressure necessitates minute recalibration — each segment readjusts accordingly.

Finally, there are the mirrors themselves. Typically the high grade glass used in telescope mirrors is ground and polished in a slow and meticulous process taking up to one year.

Kino states, “We succeeded in developing a new method that grinds the mirrors at higher speed but with extreme precision, up to a point just short of the final processing step.” This resulted in a reduction of time to just one month.

An additional benefit of this new technology development is that it is scalable. Initial plans for Seimei actually intended it to be much bigger. However, building a medium-sized scope has dramatically reduced costs and resulted in significant weight reduction.

Now that the technology baseline has been established, building further advanced telescopes will take considerably less time. And in fact plans to build a successor near the equator in Indonesia are already in the making.

From the drawing board to the future

Like many groundbreaking scientific endeavors, the Okayama 3.8M Telescope took a dedicated team over a decade to complete. Even after the project got its start in 2006, the mirror grinding technology was only perfected in 2012. Public funding was first acquired in 2015, allowing for completion of the telescope, with additional funding obtained in 2016 for building the dome on the grounds of the Okayama Observatory. In the fall of 2017 a public call for a nickname was announced, resulting in over 1,000 responses coming in from across the globe, leading to an announcement in April 2018 of the name Seimei.

The drive and curiosity of the researchers who have made this possible are as boundless as the universe to which they lift their eyes. In the coming months and years — as Seimei’s mirrors reflect the heavens — these dedicated stargazers hope to discover and understand the most elusive phenomena of the cosmos, while blazing a new path for those who will follow.

Seimei’s official website (in Japanese) is at www.kusastro.kyoto-u.ac.jp/psmt

- March 2018: With the dome opened, Seimei is in position to scan the heavens; the name also means ‘life’ in Japanese, a reference to the hope that the telescope may also assist in the search for life elsewhere in the cosmos

- March 2018: The exterior of the dome housing Seimei

- March 2018: Kino unwraps a mirror segment

- March 2018: An actuator for controlling an individual segment

- March 2018: Other facilities at the Okayama Astrophysical Observatory complex

- July 2018: The Seimei team with the completed scope, including Project Leader Tetsuya Nagata (front center with helmet) and (to his right) Project Manager Mikio Kurita